Related Accessories

Product Description

Overview

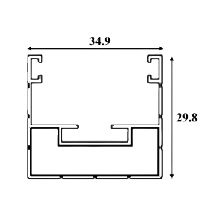

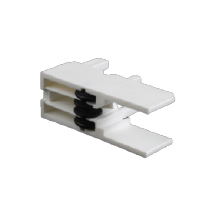

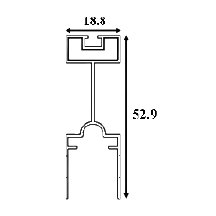

It is a folding system that can be applied very easily with its decorative and aesthetic aspects in the areas where pleated mosquito nets are applied. The mesh used in the system is of polyester material and is 100% domestic production. It can be applied to all kinds of joinery including PVC, Aluminum, Wood, Iron etc. Two different frame profile designs were made for the pleated fly screen system. Eco frame profile is preferred in sliding joinery without high handle and latch. The profile we call the luxury frame, on the contrary to the Eco frame profile, is used in sliding joinery with high handles. Wind resistance has been increased with the curved pleats of mesh, the first ropes starting at the same level as the profiles, and the wicks we call filling elements inside and outside the profiles; Safety against flies and insects is also given priority. Thanks to the fact that the system has a single frame, the stock cost and waste cost are reduced. Since no spring or other component is used, it provides the possibility to stay fixed at the desired position thanks to the adjustment stops. At the top and bottom of the sliding profiles, which are used to open and close the system, pulleys for ease of displacement of the ropes and wheels are mounted in the sliding wedge. In this way, the system not only enables even a small child to open and close it easily, but also solves the reverse movement issue of the ropes and provides a solution to the rope breakage caused by friction. Even in winter, the system is protected against all kinds of weather conditions by keeping the mosquito net closed without being dismantled. It is a system that can be shipped disassembled, easily installed and assembled. Aluminum profiles produced by extrusion achieve the desired color and appearance with electrostatic painting and wood transfer system. The materials used in the production of pleated mosquito nets directly affect the working principles. For this reason, all materials that come into direct contact with the rope must be completely plastic and UV resistant. Especially the PVC strips, which are used to fix the mesh to the profile and the so-called mounting elements such as corner wedges, slide wedges, and stops, must be manufactured from the original raw material. Otherwise, color changes caused by sunlight, loss of strength, deformations occur and prevent the system from working. As stated above, in the pleated flyscreen system we have designed, special attention has been paid to the fact that the materials are produced from original raw materials, and that the starting ropes, which allow the mesh to stand properly and vertically in the profile, start at the same level as the profile. Because if the starting ropes starts above the profile line, it means that the wind will remove the mesh from the profile, at which time the flyscreen loses its purpose. The second reason is that the starting ropes and the wick we call the filling element are of great importance in order to prevent insects such as cockroaches and small animals like mice from passing between the mesh and the profile. In order to evacuate the accumulated water and dust without being affected by external factors such as rain and dust, our mosquito net, which is kept in the closed position without removing it even in the winter as we mentioned before, has discharge outlets to the corner wedges. In this way, the exposure of the ropes to water and dust in the profiles is prevented, and the causes of rope breakage are reduced. At the same time, the reproduction of infections that are harmful to our health is not allowed, even for a bit.

Vertically-Operated

It works vertically (top-down). It is one of the way the pleated mosquito net works. It is due to the narrow width of the applied area. This mode of operation is used where we do not want the width of the sliding profile to narrow the field of view due to its small width.

Horizontally-Operated The horizontal (from left to right or vice versa) pleated fly screen is generally the preferred system when the measurements in the applied areas do not have a narrow width. The horizontal system works more comfortably than the vertical system. |

Double wing Double wings are used in places where the application areas are large. Because in areas exceeding 150 cm, it is necessary to divide it into 2 for the system to work ergonomically. This increases its resistance to the wind. |

Mobile system It is used where the applied area has double wing sliding joinery. Because the joinery can be opened and closed from both sides. Naturally, since the mosquito net should be directly proportional to the joinery, a mobile system is applied in these places. |